Nernst Lamp at the Exposition. Scientific American 83 (1900) 138, 1900-09-01

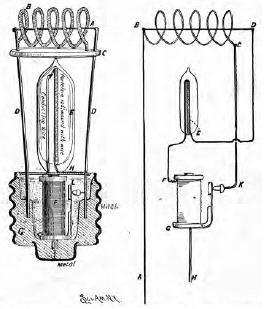

One of the most interesting displays in the Electrical Palace is that of the Nernst lamp shown in the pavilion erected by the Allgemeine Elektricitätsgesellschaft. Two different types of the Nernst lamp are made at present; in the first it is necessary to heat the conducting filament by a match, an alcohol lamp, or the like. The general appearance of this type of lamp will be seen in our engraving. From the base project two metal rods, which are braced at the ends by a short tube of porcelain, and to the ends of the rods is soldered a rather thick platinum wire; to this wire the ends of the conducting filament are soldered by a process analogous to that employed for the incandescent lamp. This filament, made up of refractory oxides, is perfectly white and homogeneous, resembling otherwise a short carbon filament. As the resistance of the filament diminishes when in a state of incandescence, it becomes necessary to insert a resistance in the circuit to cut down the current to the right amount.

The form of resistance used here is shown below the porcelain rod: a very fine platinum wire is wound around a porcelain rod about one inch long, and this is contained in a small glass bulb; the outer end of the wire is connected with a stout wire which passes back parallel to the rod. The terminals are formed of two wires fused into the glass. A lamp base of the ordinary Edison, or screw type, is used, to which is fitted a globe somewhat resembling an ordinary incandescent lamp globe; this, however, is open at the end and serves only to protect the filament from dust, etc. When the flame of a match is applied to the filament, it soon commences to glow, and finally reaches a brilliant incandescence, giving off a white light which is very pleasing in color. The light is much whiter than that given by a carbon filament, owing to the higher temperature of the refractory oxides, and is entirely free from the disagreeable green hue of the Welsbach burner.

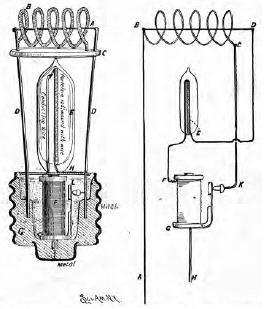

It is, of course, quite desirable to have a lamp which is entirely automatic in its action, particularly when it is placed in inaccessible positions, and accordingly an automatic form has been devised, in which the filament is heated by the passage of current through an exterior conductor, and when its resistance has been thus reduced and it allows the passage of a sufficient current to bring it to incandescence, the circuit of the heating conductor is interrupted by a special device. The general disposition of the working parts is seen in the sectional view. From the socket rise two stout wires, D D, which support a porcelain disk, C. Upon the disk is supported the filament, A, and surrounding it is a spiral tube of porcelain, B. The porcelain tube carries on its surface a great number of turns of fine platinum wire, which has been wound on while the tube is still straight and before baking the porcelain; the wire is almost completely imbedded in the porcelain and is visible only upon close examination.

Automatic Type - Sectional View and Diagram of Wiring.

This exterior tube serves to heat the filament by the passage of current in the fine platinum wire; a thick wire, not shown in the diagram, passes below from the right-hand end. A small glass bulb placed below contains the resistance wire, wound around a porcelain rod, E. This resistance is of the same type as for the first lamp, only one form being used throughout. The lamp base, G, resembles the ordinary screw type, but the interior body, of porcelain, is recessed to receive the automatic cut-out device; it also supports the wires, D D. The cut-out consists of a small electromagnet, F, fitting in the cavity of the socket; the upper end of the bobbin is of soft iron, and below an iron piece curves up and supports a small armature, L, by means of a flat spring. The armature rests normally against a contact piece to the right, but when a sufficient current passes in the coil, the armature is attracted and leaves the contact point, thus cutting off the current from the heating spiral. The action will be clearly seen by referring to the diagram of the electrical connections. The current takes two paths; first, through the filament, the resistance bulb and the magnet, following the circuit, A, B, D, E, F, G, H; or, second, through the heating spiral, the contact, K, the armature of the magnet, and return, or A, B, C, K, H. Owing to the high resistance of the filament when cold, the current passing in the circuit of the magnet is not sufficient at first to attract the armature, but a few seconds after it is turned on the spiral commences to heat up, and the temperature of the filament is raised sufficiently to allow a large current to pass; it thus becomes incandescent, and, its resistance being lowered, a large current passes in the magnet; the armature is attracted and the circuit of the heating spiral broken at K. When the lamp is turned off, the reverse action takes place; contact is made at K, restoring the original conditions.

Nernst Lamp - Original Type.

Chandelier of Nernst Lamps.

The price of a lamp with the automatic illuminating device is, of course, much higher than for the ordinary type, on account of the two extra pieces, the magnet and the heating spiral. The magnet, of course, does not deteriorate; the spiral, being subject to alternate expansions and contractions, lasts a reasonable length of time, but not indefinitely. It is, however, easily replaced, and is taken back for two-thirds of its original value. It is probable, besides, that the platinum wire will be replaced by a material which will give the same service at a less cost. The parts of the lamp which need to be replaced, the spiral and the filament, cost but little, and it is estimated that the cost of lamp renewals is not greater than in the case of the ordinary incandescent lamp. The duration of the filament depends somewhat upon the manner in which it is brought to incandescence, whether heated quickly and thus subjected to a violent rush of current; etc. In general, it is less than that of a carbon filament; if the changes in voltage do not greatly exceed the normal, one may count upon an average life of 300 hours for this lamp. The life is diminished gradually by a molecular change, which is produced little by little under the action of heat, accompanied by a diminution of solidity and often an increase of resistance which diminishes its brightness. The expenditure of energy in the present type of Nernst lamp is from l 1/2 to 1 3/4 watts per candle power, which is about one-half that of an incandescent lamp; for a 16-candle power lamp the energy consumed is thus from 24 to 28 watts, representing 27 to 30 lamps per horse power. At present the Nernst lamp is manufactured for 25, 50, and 100 candle power, under a tension of 110 or 220 volts.

Revised 2010-10-13